- +91 9108006731

- sales@filprosensors.com

A level sensor is an essential device used to measure the level of liquids or solids in various applications. Read on to learn more about its functions, types, and benefits.

Level sensors are used in various industries, including pharmaceuticals, food and beverage, oil and gas, and wastewater treatment. They are designed to detect the level of liquids, solids, and slurries in tanks, vessels, and other containers. A level sensor measures the distance from the sensor to the surface of the material being measured and provides accurate data that helps operators monitor, control, and optimize their processes. In this article, we will discuss level sensors in detail, including their types, benefits, and applications.

Contact level sensors come in direct contact with the material being measured. They are designed to measure the level of liquids, powders, and granules in containers. Contact sensors include:

Non-contact level sensors do not touch the material being measured. They use various technologies such as light, radar, and sound waves to measure the level of liquids, powders, and granules in containers. Non-contact sensors include:

Q: What is a level sensor used for?

A: A level sensor is used to measure the level of liquids, solids, and slurries in tanks, vessels, and other containers in various industries.

Q: What types of level sensors are available?

A: There are two types of level sensors: contact and non-contact sensors. Contact sensors include float, conductivity, capacitance, ultrasonic, magnetic, and hydrostatic sensors. Non-contact sensors include optical, infrared, radar, laser, and microwave sensors.

Q: What are the benefits of using a level sensor?

A: Level sensors provide accurate measurement of liquid and solid levels, improved safety, reduced downtime, increased efficiency, lower maintenance costs, and enhanced productivity and profitability.

Level sensors are critical devices used in various industries to measure the level of liquids, solids, and slurries in containers. They provide accurate data that helps operators monitor and control their processes, reduce downtime, and enhance productivity and profitability. There are two types of level sensors: contact and non-contact sensors, each with its own advantages and disadvantages. Regardless of the type of level sensor used, its benefits are numerous, and it is an essential tool for any process where liquid or solid levels need to be monitored and controlled.

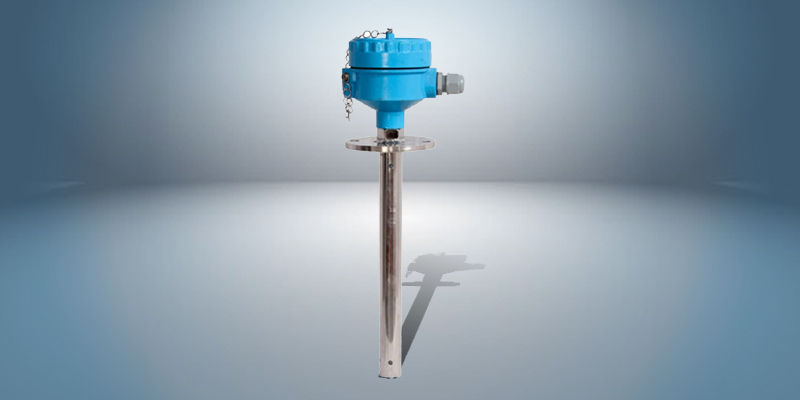

Filpro Fuel level sensoris a low cost capacitance type level sensor. It is designed for monitoring levels in fuel tanks of vehicles, Bulk storage tanks fitted on vehicles, diesel storage tanks.

The Design is simple & light weight. It measures the level accurately and reliably. The sensor output is connected to vehicle monitoring and tracking system or level indicators.

The sensor consists of measuring probe which is encircled with a reference probe. This given more linear output and is not affected by turbulence inside the tank.

Fuel Level Sensor As the fuel level increases, the capacitance value also increases. The fuel acts as the dielectric between electrodes. The increase in capacitance directly proportional to increase in fuel level. This change in capacitance is measured and converted into 4-20mA, 0-5V, 0-10V, RS485 O/P.

| Wetted parts | Aluminium / SS | ||

| Flange | Aluminium / MS / SS | ||

| Enclosure | Aluminium / Plastic | ||

| Probe Length | 300mm to 3000mm | ||

| Input | 12V DC / 24V Description | ||

| Output | 4-20mA, 0-10V DC, RS 485 | ||